Product Description

ÖLFLEX® CLASSIC FD 810 CY

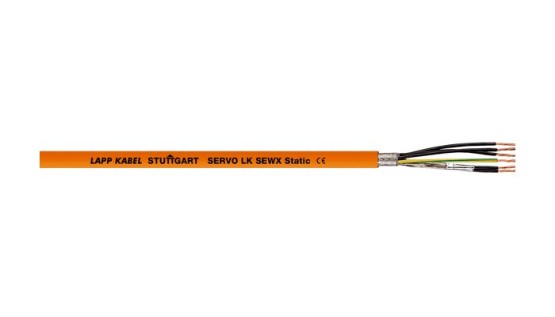

SERVO Cables in acc. to SEW® Standard

Servo cable, approved

Multi-standard approval reduces part varieties and saves costs

- Servo drives

- EMC-compliant

|

|

|

|

|

SKU: 100000071

Categories: CABLES & ACCESSORIES, Power and control cables, PVC sheath - approved, Servo applications

Article List

Product description

Technical Data

| Lapp No. | Product Name | Datasheet / Product video | Request Quote | ||||

|---|---|---|---|---|---|---|---|

| Number of cores and mm² per conductor | Outer diameter (mm) | Copper index (kg/km) | Weight (kg/km) | ||||

| Servo cables | |||||||

| Lapp 0038060 | SERVO Cables in acc. to SEW Standard 4 G 1,5 + (3 x 1,0) | ||||||

| 4 G 1,5 + (3 x 1,0) | 11,8 | 151.0 | 300 | ||||

| Lapp 0038061 | SERVO Cables in acc. to SEW Standard 4 G 2,5 + (3 x 1,0) | ||||||

| 4 G 2,5 + (3 x 1,0) | 13,4 | 212.9 | 370 | ||||

| Lapp 0038062 | SERVO Cables in acc. to SEW Standard 4 G 4 + (3 x 1,0) | ||||||

| 4 G 4 + (3 x 1,0) | 15.0 | 281.8 | 476 | ||||

| Lapp 0038063 | SERVO Cables in acc. to SEW Standard 4 G 6 + (3 x 1,5) | ||||||

| 4 G 6 + (3 x 1,5) | 17.0 | 392.8 | 625 | ||||

| Lapp 0038064 | SERVO Cables in acc. to SEW Standard 4 G 10 + (3 x 1,5) | ||||||

| 4 G 10 + (3 x 1,5) | 20.0 | 625.1 | 1024 | ||||

Application range

- Specially designed to connect SEW servomotors

- Connecting cable between servo controller and motor

- Plant engineering

- Machine tools

- Printing machines

Benefits

- Multi-standard approval reduces part varieties and saves costs

Product Make-up

- Fine-wire strand made of bare copper wires

- Core insulation: TPE

- Control core triplet with laminated aluminium film and a layer of tinned-copper wires

- Cores twisted in short lay lengths

- Tinned-copper braiding

- PVC outer sheath, orange (RAL 2003)

Norm references / Approvals

- UL-AWM-Style 2570

- Based on VDE 0250 / 0285

- UL File No. E63634

Product features

- For fixed installation or applications with occasional movements

- Oil-resistant

- Flame-retardant according IEC 60332-1-2

- Flame-retardant according to UL VW1/CSA FT1

| Core identification code | Power: black cores with U, VV, WWW printing and 1 core gnye Control cores: black cores with numbers 1, 2 and 3 |

| Conductor stranding | Fine wire according to VDE 0295 Class 5/ IEC 60228 Class 5 |

| Minimum bending radius | Occasional flexing: 15 x outer diameter Fixed installation: 4 x outer diameter |

| Nominal voltage | Power cores: IEC 750 V, UL 600 V Control cores: 1 mm² and 1.5 mm: IEC 350 V, UL 600 V |

| Test voltage | 2000 V |

| Protective conductor | G = with GN-YE protective conductor |

| Temperature range | Flexing: -10°C to +80°C Fixed installation: -40°C to +80°C |

Product information (PDF)

Product information (PDF)