Product Description

ÖLFLEX® EB CY

ÖLFLEX® 550 P*

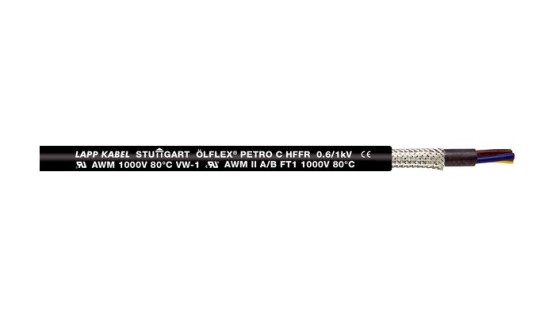

ÖLFLEX® PETRO C HFFR

Chemically and mechanically robust cables for harsh environmental conditions – 0.6/1 kV

Resistant to contact with many mineral oil-based lubricants, diluted acids, aqueous alkaline solutions and other chemical media; Reduced flame spreading increase the protection against damage to persons and property in the event of a fire; The copper braiding serves as an electromagnetic screen and can also be used as armouring (Braid Armour); Can be used in many applications from different industries, as it has remarkable mechanical, thermal and chemical properties

- Oil and mud-resistant according toIEC 61892-4, Annex D

- Highly flame retardant

- UL/cUL approved for North America

|

|

|

|

|

|

|

|

|

|

|

|

|

SKU: 100000038

Categories: CABLES & ACCESSORIES, Harsh conditions, High mechanical and chemical resistance, Power and control cables

Article List

Product description

Technical Data

| Lapp No. | Product Name | Datasheet / Product video | Request Quote | ||||

|---|---|---|---|---|---|---|---|

| Number of cores and mm² per conductor | Outer diameter (mm) | Copper index (kg/km) | Weight (kg/km) | ||||

| ÖLFLEX® PETRO C HFFR black – single core | |||||||

| Lapp 0023249 | ÖLFLEX PETRO C HFFR 1 X 70 | ||||||

| 1 X 70 | 19,3 | 737.0 | 948 | ||||

| Lapp 0023250 | ÖLFLEX PETRO C HFFR 1 X 95 | ||||||

| 1 X 95 | 21,6 | 1002.0 | 1155 | ||||

| Lapp 0023251 | ÖLFLEX PETRO C HFFR 1 X 120 | ||||||

| 1 X 120 | 24,5 | 1254.0 | 1463 | ||||

| Lapp 0023248 | ÖLFLEX PETRO C HFFR 1 X 150 | ||||||

| 1 X 150 | 26,1 | 1553.0 | 1767 | ||||

| Lapp 0023233 | ÖLFLEX PETRO C HFFR 1 X 185 | ||||||

| 1 X 185 | 28,4 | 1912.0 | 2349 | ||||

| Lapp 0023234 | ÖLFLEX PETRO C HFFR 1 X 240 | ||||||

| 1 X 240 | 32,6 | 2475.0 | 2869 | ||||

| Lapp 0023279 | ÖLFLEX PETRO C HFFR 1 X 300 | ||||||

| 1 X 300 | 34,7 | 3075.0 | 3817 | ||||

| ÖLFLEX® PETRO C HFFR black – multi-core | |||||||

| Lapp 0023275 | ÖLFLEX PETRO C HFFR 3 G 0,5 | ||||||

| 3 G 0,5 | 10,1 | 36.0 | 140 | ||||

| Lapp 0023274 | ÖLFLEX PETRO C HFFR 2 X 1,0 | ||||||

| 2 X 1,0 | 10,5 | 41.0 | 149 | ||||

| Lapp 0023252 | ÖLFLEX PETRO C HFFR 2 X 1,5 | ||||||

| 2 X 1,5 | 11,5 | 57.0 | 183 | ||||

| Lapp 0023253 | ÖLFLEX PETRO C HFFR 3 G 1,5 | ||||||

| 3 G 1,5 | 12.0 | 72.0 | 212 | ||||

| Lapp 0023254 | ÖLFLEX PETRO C HFFR 4 G 1,5 | ||||||

| 4 G 1,5 | 12,8 | 90.0 | 249 | ||||

| Lapp 0023255 | ÖLFLEX PETRO C HFFR 5 G 1,5 | ||||||

| 5 G 1,5 | 14.0 | 115.0 | 307 | ||||

| Lapp 0023256 | ÖLFLEX PETRO C HFFR 7 G 1,5 | ||||||

| 7 G 1,5 | 15,9 | 151.0 | 401 | ||||

| Lapp 0023239 | ÖLFLEX PETRO C HFFR 12 G 1,5 | ||||||

| 12 G 1,5 | 18,8 | 238.0 | 573 | ||||

| Lapp 0023257 | ÖLFLEX PETRO C HFFR 18 G 1,5 | ||||||

| 18 G 1,5 | 22,3 | 350.0 | 846 | ||||

| Lapp 0023240 | ÖLFLEX PETRO C HFFR 25 G 1,5 | ||||||

| 25 G 1,5 | 26,6 | 490.0 | 1183 | ||||

| Lapp 0023278 | ÖLFLEX PETRO C HFFR 3 G 2,5 | ||||||

| 3 G 2,5 | 13,5 | 105.0 | 276 | ||||

| Lapp 0023242 | ÖLFLEX PETRO C HFFR 4 G 2,5 | ||||||

| 4 G 2,5 | 14,6 | 147.0 | 347 | ||||

| Lapp 0023244 | ÖLFLEX PETRO C HFFR 5 G 2,5 | ||||||

| 5 G 2,5 | 15,7 | 171.0 | 401 | ||||

| Lapp 0023245 | ÖLFLEX PETRO C HFFR 7 G 2,5 | ||||||

| 7 G 2,5 | 18,3 | 233.0 | 547 | ||||

| Lapp 0023258 | ÖLFLEX PETRO C HFFR 12 G 2,5 | ||||||

| 12 G 2,5 | 22,3 | 378.0 | 840 | ||||

| Lapp 0023260 | ÖLFLEX PETRO C HFFR 4 G 4 | ||||||

| 4 G 4 | 16,2 | 212.0 | 457 | ||||

| Lapp 0023266 | ÖLFLEX PETRO C HFFR 5 G 4 | ||||||

| 5 G 4 | 17,6 | 250.0 | 540 | ||||

| Lapp 0023261 | ÖLFLEX PETRO C HFFR 4 G 6 | ||||||

| 4 G 6 | 17,7 | 288.0 | 558 | ||||

| Lapp 0023268 | ÖLFLEX PETRO C HFFR 5 G 6 | ||||||

| 5 G 6 | 19,9 | 367.0 | 710 | ||||

| Lapp 0023280 | ÖLFLEX PETRO C HFFR 4 G 10 | ||||||

| 4 G 10 | 22,3 | 474.0 | 882 | ||||

| Lapp 0023272 | ÖLFLEX PETRO C HFFR 5 G 10 | ||||||

| 5 G 10 | 24,3 | 582.0 | 1069 | ||||

| Lapp 0023281 | ÖLFLEX PETRO C HFFR 4 G 16 | ||||||

| 4 G 16 | 24,9 | 716.0 | 1208 | ||||

| Lapp 0023269 | ÖLFLEX PETRO C HFFR 5 G 16 | ||||||

| 5 G 16 | 27,6 | 881.0 | 1483 | ||||

| Lapp 0023267 | ÖLFLEX PETRO C HFFR 4 G 25 | ||||||

| 4 G 25 | 30,2 | 1096.0 | 1785 | ||||

| Lapp 0023270 | ÖLFLEX PETRO C HFFR 5 G 25 | ||||||

| 5 G 25 | 33,4 | 1371.0 | 2206 | ||||

| Lapp 0023262 | ÖLFLEX PETRO C HFFR 4 G 35 | ||||||

| 4 G 35 | 33,6 | 1515.0 | 2314 | ||||

| Lapp 0023282 | ÖLFLEX PETRO C HFFR 5 G 35 | ||||||

| 5 G 35 | 37,1 | 1875.0 | 2847 | ||||

| Lapp 0023246 | ÖLFLEX PETRO C HFFR 4 G 50 | ||||||

| 4 G 50 | 39,3 | 2140.0 | 3264 | ||||

| Lapp 0023271 | ÖLFLEX PETRO C HFFR 5 G 50 | ||||||

| 5 G 50 | 43,4 | 2620.0 | 4002 | ||||

| ÖLFLEX® PETRO C HFFR blue – multi-core | |||||||

| Lapp 0023276 | ÖLFLEX PETRO C HFFR 3 G 0,5 | ||||||

| 3 G 0,5 | 10,1 | 36.0 | 140 | ||||

| Lapp 0023273 | ÖLFLEX PETRO C HFFR 2 X 1,0 | ||||||

| 2 X 1,0 | 10,5 | 41.0 | 147 | ||||

| Lapp 0023263 | ÖLFLEX PETRO C HFFR 2 X 1,5 | ||||||

| 2 X 1,5 | 11,5 | 57.0 | 183 | ||||

| Lapp 0023283 | ÖLFLEX PETRO C HFFR 3 G 1,5 | ||||||

| 3 G 1,5 | 12.0 | 72.0 | 212 | ||||

| Lapp 0023237 | ÖLFLEX PETRO C HFFR 4 G 1,5 | ||||||

| 4 G 1,5 | 12,8 | 90.0 | 249 | ||||

| Lapp 0023284 | ÖLFLEX PETRO C HFFR 5 G 1,5 | ||||||

| 5 G 1,5 | 14.0 | 115.0 | 307 | ||||

| Lapp 0023238 | ÖLFLEX PETRO C HFFR 7 G 1,5 | ||||||

| 7 G 1,5 | 15,9 | 151.0 | 401 | ||||

| Lapp 0023264 | ÖLFLEX PETRO C HFFR 12 G 1,5 | ||||||

| 12 G 1,5 | 18,8 | 238.0 | 573 | ||||

| Lapp 0023265 | ÖLFLEX PETRO C HFFR 25 G 1,5 | ||||||

| 25 G 1,5 | 26,6 | 490.0 | 1183 | ||||

Application range

- Onshore and offshore applications

- For electrical connection of drilling units, pumping stations, compressors or generators in harsh environmental conditions

Benefits

- Resistant to contact with many mineral oil-based lubricants, diluted acids, aqueous alkaline solutions and other chemical media

- Reduced flame spreading increase the protection against damage to persons and property in the event of a fire

- The copper braiding serves as an electromagnetic screen and can also be used as armouring (Braid Armour)

- Can be used in many applications from different industries, as it has remarkable mechanical, thermal and chemical properties

Product Make-up

- Fine-wire, tinned-copper conductor

- Core insulation: polyolefin compound

- Cores twisted in layers

- Inner sheath: halogen-free compound

- Tinned copper screen braiding

- Outer sheath made of robust special polymer, colour black

Norm references / Approvals

- Single-core versions:

USA: UL AWM Style 10587

Canada: cUL AWM II A/B - Multi-core versions:

USA: UL AWM Style 20234

Canada: cUL AWM II A/B

Product features

- Oil-resistant acc. to NEK TS 606:2009

Oil and mud-resistant according to

IEC 61892-4, Annex D - Fire behaviour:

– Halogen-free (VDE 0472-815)

– Flame-retardant (IEC 60332-1-2)

– No flame propagation (IEC 60332-3-22

Cat. A) - UV-resistant according to ISO 4892-2

- Ozone-resistant according to EN 50396

- Salt water-resistant according to UL 1309

| Core identification code | Colours according to VDE 0293-308, refer to Appendix T9 From 6 cores: black with white numbers |

| Fire test | Flame-retardant acc. to IEC 60332-1-2, UL VW-1, Cable Flame Test, CSA FT 1 No flame-propagation according to IEC 60332-3-22 category A |

| Classification | ETIM 5.0 Class-ID: EC000057 ETIM 5.0 Class-Description: Low voltage power cable |

| Conductor stranding | Fine wire acc. to VDE 0295, class 5 / IEC 60228 class 5 from 0.5 mm² |

| Minimum bending radius | Occasional flexing: 20 x outer diameter Fixed installation: 6 x outer diameter |

| Nominal voltage | IEC U0/U: 600/1000 V Up to 1.0mm² 300/500 V |

| Test voltage | 4000 V |

| Temperature range | Occasional flexing: -40°C to +90°C According to UL/AWM: -40°C to +80°C Fixed installation: -50°C to +90°C according to UL/AWM: -50°C to +80°C |

Product information (PDF)

Product information (PDF)