Product Description

ÖLFLEX® TRUCK 170 FLRYY

ÖLFLEX® HEAT 260 SC

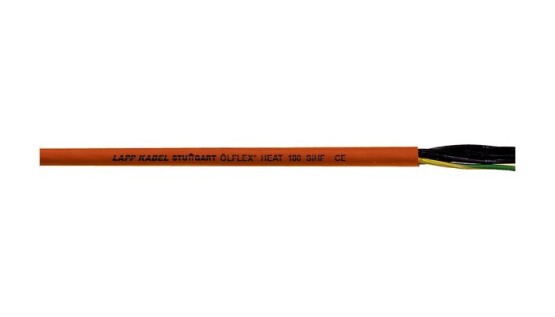

ÖLFLEX® HEAT 180 SiHF

Silicone cables with extended temperature range

Flexibility simplifies installation where space is limited; Possesses insulating properties after combustion due to remaining SiO2 ash on the conductor

- The classic for multi-functional use

|

|

|

|

|

SKU: 100000139

Categories: CABLES & ACCESSORIES, Expanded ambient temperatures, Power and control cables, Silicone cables (-50°C to +180°C)

Article List

Product description

Technical Data

| Lapp No. | Product Name | Datasheet / Product video | Request Quote | ||||

|---|---|---|---|---|---|---|---|

| Number of cores and mm² per conductor | Outer diameter (mm) | Copper index (kg/km) | Weight (kg/km) | ||||

| ÖLFLEX® HEAT 180 SiHF | |||||||

| Lapp 0046001 | ÖLFLEX HEAT 180 SiHF 2 X 0,75 | ||||||

| 2 X 0,75 | 6,4 | 14.4 | 59 | ||||

| Lapp 0046002 | ÖLFLEX HEAT 180 SiHF 3 G 0,75 | ||||||

| 3 G 0,75 | 6,8 | 21.6 | 70 | ||||

| Lapp 00460033 | ÖLFLEX HEAT 180 SiHF 4 G 0,75 | ||||||

| 4 G 0,75 | 7,6 | 28.8 | 89 | ||||

| Lapp 00460043 | ÖLFLEX HEAT 180 SiHF 5 G 0,75 | ||||||

| 5 G 0,75 | 8,5 | 36.0 | 112 | ||||

| Lapp 0046005 | ÖLFLEX HEAT 180 SiHF 6 G 0,75 | ||||||

| 6 G 0,75 | 9,2 | 43.2 | 131 | ||||

| Lapp 0046006 | ÖLFLEX HEAT 180 SiHF 7 G 0,75 | ||||||

| 7 G 0,75 | 9,2 | 50.4 | 136 | ||||

| Lapp 0046007 | ÖLFLEX HEAT 180 SiHF 2 X 1 | ||||||

| 2 X 1 | 6,6 | 19.2 | 66 | ||||

| Lapp 0046008 | ÖLFLEX HEAT 180 SiHF 3 G 1 | ||||||

| 3 G 1 | 7.0 | 29.0 | 79 | ||||

| Lapp 00460093 | ÖLFLEX HEAT 180 SiHF 4 G 1 | ||||||

| 4 G 1 | 7,9 | 38.4 | 101 | ||||

| Lapp 00460103 | ÖLFLEX HEAT 180 SiHF 5 G 1 | ||||||

| 5 G 1 | 8,8 | 48.0 | 127 | ||||

| Lapp 0046012 | ÖLFLEX HEAT 180 SiHF 7 G 1 | ||||||

| 7 G 1 | 9,5 | 67.0 | 156 | ||||

| Lapp 0046013 | ÖLFLEX HEAT 180 SiHF 2 X 1,5 | ||||||

| 2 X 1,5 | 7,6 | 29.0 | 90 | ||||

| Lapp 0046014 | ÖLFLEX HEAT 180 SiHF 3 G 1,5 | ||||||

| 3 G 1,5 | 8.0 | 43.0 | 109 | ||||

| Lapp 00460153 | ÖLFLEX HEAT 180 SiHF 4 G 1,5 | ||||||

| 4 G 1,5 | 8,8 | 58.0 | 134 | ||||

| Lapp 00460163 | ÖLFLEX HEAT 180 SiHF 5 G 1,5 | ||||||

| 5 G 1,5 | 9,6 | 72.0 | 163 | ||||

| Lapp 0046018 | ÖLFLEX HEAT 180 SiHF 7 G 1,5 | ||||||

| 7 G 1,5 | 10,4 | 101.0 | 202 | ||||

| Lapp 0046039 | ÖLFLEX HEAT 180 SiHF 12 G 1,5 | ||||||

| 12 G 1,5 | 14.0 | 173.0 | 361 | ||||

| Lapp 0046040 | ÖLFLEX HEAT 180 SiHF 16 G 1,5 | ||||||

| 16 G 1,5 | 16,2 | 230.4 | 478 | ||||

| Lapp 0046041 | ÖLFLEX HEAT 180 SiHF 20 G 1,5 | ||||||

| 20 G 1,5 | 17,5 | 288.0 | 574 | ||||

| Lapp 0046042 | ÖLFLEX HEAT 180 SiHF 24 G 1,5 | ||||||

| 24 G 1,5 | 19,8 | 345.6 | 720 | ||||

| Lapp 0046019 | ÖLFLEX HEAT 180 SiHF 2 X 2,5 | ||||||

| 2 X 2,5 | 8,8 | 48.0 | 128 | ||||

| Lapp 0046020 | ÖLFLEX HEAT 180 SiHF 3 G 2,5 | ||||||

| 3 G 2,5 | 9,7 | 72.0 | 167 | ||||

| Lapp 00460213 | ÖLFLEX HEAT 180 SiHF 4 G 2,5 | ||||||

| 4 G 2,5 | 10,6 | 96.0 | 206 | ||||

| Lapp 00460223 | ÖLFLEX HEAT 180 SiHF 5 G 2,5 | ||||||

| 5 G 2,5 | 11,6 | 120.0 | 251 | ||||

| Lapp 0046024 | ÖLFLEX HEAT 180 SiHF 7 G 2,5 | ||||||

| 7 G 2,5 | 12,6 | 168.0 | 313 | ||||

| Lapp 0046025 | ÖLFLEX HEAT 180 SiHF 2 X 4 | ||||||

| 2 X 4 | 10,8 | 76.8 | 196 | ||||

| Lapp 0046026 | ÖLFLEX HEAT 180 SiHF 3 G 4 | ||||||

| 3 G 4 | 11,5 | 115.0 | 241 | ||||

| Lapp 00460273 | ÖLFLEX HEAT 180 SiHF 4 G 4 | ||||||

| 4 G 4 | 12,6 | 154.0 | 300 | ||||

| Lapp 00460283 | ÖLFLEX HEAT 180 SiHF 5 G 4 | ||||||

| 5 G 4 | 14.0 | 192.0 | 374 | ||||

| Lapp 0046030 | ÖLFLEX HEAT 180 SiHF 7 G 4 | ||||||

| 7 G 4 | 15,6 | 269.0 | 486 | ||||

| Lapp 0046031 | ÖLFLEX HEAT 180 SiHF 2 X 6 | ||||||

| 2 X 6 | 12,4 | 116.0 | 268 | ||||

| Lapp 0046032 | ÖLFLEX HEAT 180 SiHF 3 G 6 | ||||||

| 3 G 6 | 13,2 | 173.0 | 333 | ||||

| Lapp 00460333 | ÖLFLEX HEAT 180 SiHF 4 G 6 | ||||||

| 4 G 6 | 14,7 | 230.0 | 425 | ||||

| Lapp 00460343 | ÖLFLEX HEAT 180 SiHF 5 G 6 | ||||||

| 5 G 6 | 16,6 | 288.0 | 538 | ||||

| Lapp 0046036 | ÖLFLEX HEAT 180 SiHF 7 G 6 | ||||||

| 7 G 6 | 18,6 | 403.0 | 705 | ||||

| Lapp 00460373 | ÖLFLEX HEAT 180 SiHF 4 G 10 | ||||||

| 4 G 10 | 19,4 | 384.0 | 707 | ||||

| Lapp 00460453 | ÖLFLEX HEAT 180 SiHF 5 G 10 | ||||||

| 5 G 10 | 21,6 | 480.0 | 878 | ||||

| Lapp 00460383 | ÖLFLEX HEAT 180 SiHF 4 G 16 | ||||||

| 4 G 16 | 21,4 | 614.0 | 1004 | ||||

Application range

- Areas with high ambient temperatures where insulating and sheath materials of conventional cables will embrittle after a short while

- Typical fields of application

– Steel, ceramic and iron works

– Bakery equipment and industrial furnaces

– Electric motor industry

– Sauna/solarium construction

– Thermal and heating elements

– Lighting technology

– Ventilator engineering

– Air-conditioning technology

– Galvanisation technology

Benefits

- Flexibility simplifies installation where space is limited

- Possesses insulating properties after combustion due to remaining SiO2 ash on the conductor

Product Make-up

- Fine-wire, tinned-copper conductor

- Silicone-based core insulation

- Cores twisted in layers

- Silicone-based outer sheath,

colour red-brown

Product features

- Halogen-free and flame-retardant

(IEC 60332-1-2) - Resistant to a multitude of oils, alcohols, vegetable and animal fats and chemical substances

| Core identification code | Colours according to VDE 0293-308, refer to Appendix T9 From 6 cores: black with white numbers |

| Classification | ETIM 5.0 Class-ID: EC001578 ETIM 5.0 Class-Description: Flexible cable |

| Conductor stranding | Fine wire according to VDE 0295 Class 5/ IEC 60228 Class 5 |

| Minimum bending radius | Occasional flexing: 15 x outer diameter Fixed installation: 4 x outer diameter |

| Nominal voltage | U0/U: 300/500 V |

| Test voltage | 2000 V |

| Protective conductor | G = with GN-YE protective conductor X = without protective conductor |

| Temperature range | -50 °C to +180 °C (adequate ventilation required) |

Product information (PDF)

Product information (PDF)