Product Description

ÖLFLEX® HEAT 180 H05SS-F EWKF

H07V-K with

ÖLFLEX® HEAT 205 MC

Fluorinated ethylene propylene cables for harsh applications

Space and weight-saving installations due to small cable diameters; Resistant to contact with mostly all highly aggressive chemical media; Low outgassing behaviour

- Good chemical resistance

- Wide temperature application range

- Thin, light and robust

|

|

|

|

|

|

|

|

|

|

SKU: 100000146

Categories: CABLES & ACCESSORIES, Expanded ambient temperatures, FEP cables (-100°C to +205°C), Power and control cables

Article List

Product description

Technical Data

| Lapp No. | Product Name | Datasheet / Product video | Request Quote | ||||

|---|---|---|---|---|---|---|---|

| Number of cores and mm² per conductor | Outer diameter (mm) | Copper index (kg/km) | Weight (kg/km) | ||||

| ÖLFLEX® HEAT 205 MC | |||||||

| Lapp 0091200 | ÖLFLEX HEAT 205 MC 2 X 0,25 | ||||||

| 2 X 0,25 | 3,1 | 5.0 | 17.2 | ||||

| Lapp 0091201 | ÖLFLEX HEAT 205 MC 3 G 0,25 | ||||||

| 3 G 0,25 | 3,3 | 7.5 | 22.2 | ||||

| Lapp 00912023 | ÖLFLEX HEAT 205 MC 4 G 0,25 | ||||||

| 4 G 0,25 | 3,6 | 10.0 | 27.5 | ||||

| Lapp 0091210 | ÖLFLEX HEAT 205 MC 2 X 0,5 | ||||||

| 2 X 0,5 | 3,8 | 9.8 | 21.6 | ||||

| Lapp 0091211 | ÖLFLEX HEAT 205 MC 3 G 0,5 | ||||||

| 3 G 0,5 | 4.0 | 14.7 | 32.8 | ||||

| Lapp 00912123 | ÖLFLEX HEAT 205 MC 4 G 0,5 | ||||||

| 4 G 0,5 | 4,4 | 19.6 | 44.4 | ||||

| Lapp 0091220 | ÖLFLEX HEAT 205 MC 2 X 0,75 | ||||||

| 2 X 0,75 | 4,2 | 14.4 | 31.5 | ||||

| Lapp 0091221 | ÖLFLEX HEAT 205 MC 3 G 0,75 | ||||||

| 3 G 0,75 | 4,6 | 21.6 | 46.1 | ||||

| Lapp 00912223 | ÖLFLEX HEAT 205 MC 4 G 0,75 | ||||||

| 4 G 0,75 | 4,9 | 29.0 | 57.9 | ||||

| Lapp 0091230 | ÖLFLEX HEAT 205 MC 2 X 1 | ||||||

| 2 X 1 | 4,5 | 19.0 | 41.6 | ||||

| Lapp 0091231 | ÖLFLEX HEAT 205 MC 3 G 1 | ||||||

| 3 G 1 | 4,8 | 29.0 | 55.6 | ||||

| Lapp 00912323 | ÖLFLEX HEAT 205 MC 4 G 1 | ||||||

| 4 G 1 | 5,3 | 38.0 | 70 | ||||

| Lapp 0091100 | ÖLFLEX HEAT 205 MC 3 G 1,5 | ||||||

| 3 G 1,5 | 5,6 | 43.0 | 70 | ||||

| Lapp 00911033 | ÖLFLEX HEAT 205 MC 4 G 1,5 | ||||||

| 4 G 1,5 | 6,1 | 58.0 | 98 | ||||

| Lapp 00911013 | ÖLFLEX HEAT 205 MC 5 G 1,5 | ||||||

| 5 G 1,5 | 6,8 | 72.0 | 117 | ||||

| Lapp 0091102 | ÖLFLEX HEAT 205 MC 7 G 1,5 | ||||||

| 7 G 1,5 | 7,4 | 101.0 | 184 | ||||

| Lapp 0091236 | ÖLFLEX HEAT 205 MC 3 G 2,5 | ||||||

| 3 G 2,5 | 6,6 | 72.0 | 86 | ||||

| Lapp 00912353 | ÖLFLEX HEAT 205 MC 4 G 2,5 | ||||||

| 4 G 2,5 | 7,3 | 96.0 | 115 | ||||

| Lapp 00912373 | ÖLFLEX HEAT 205 MC 5 G 2,5 | ||||||

| 5 G 2,5 | 8,2 | 120.0 | 144 | ||||

| Lapp 00912423 | ÖLFLEX HEAT 205 MC 4 G 4 | ||||||

| 4 G 4 | 8,7 | 154.0 | 180 | ||||

| Lapp 00912433 | ÖLFLEX HEAT 205 MC 5 G 4 | ||||||

| 5 G 4 | 9,6 | 192.0 | 225 | ||||

Application range

- Conventional cables are not designed for use in environments with very high operating temperatures, heavy usage of chemical agents, or tight spaces

- Typical fields of application

– Industrial furnace construction

– Foundries

– Chemical industry

– Power plant engineering

– Paint shop line technology

– Heating elements

– Polymer processing

– Wind turbine engineering

Benefits

- Space and weight-saving installations due to small cable diameters

- Resistant to contact with mostly all highly aggressive chemical media

- Low outgassing behaviour

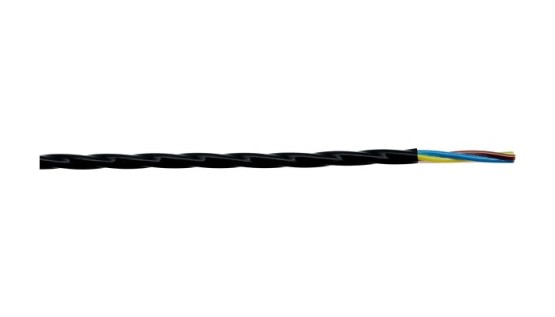

Product Make-up

- Fine-wire, tinned-copper conductor

- FEP-based core insulation

- Cores twisted together

- FEP-based outer sheath, black

Norm references / Approvals

- ÖLFLEX® HEAT 205 made of FEP

– Outstanding resistance against acids,

solvents, lacquers, petrol, oils and many

other chemical media

– Difficult to inflame

– High dielectric strength and high abrasion

resistance

– Low water absorption

– Resistant to microbes

– Adhesion free insulation materials

– Weather and ozone resistant

– Hydrophobic and dirt-repellent

– High elongation and tear resistance

– Resistant against hydraulic fluids

| Core identification code | Up to 5 cores: colour-coded acc. to VDE 0293-308 From 7 cores: ÖLFLEX® colour-codes, refer to Appendix T7 |

| Classification | ETIM 5.0 Class-ID: EC001578 ETIM 5.0 Class-Description: Flexible cable |

| Conductor stranding | Fine wire acc. to VDE 0295, class 5 / IEC 60228 class 5 from 0.5 mm² |

| Minimum bending radius | Occasional flexing: 15 x outer diameter Fixed installation: 4 x outer diameter |

| Nominal voltage | U0/U: 300/500 V |

| Test voltage | 2500 V |

| Protective conductor | G = with GN-YE protective conductor X = without protective conductor |

| Temperature range | Fixed installation: -100°C to +205°C |

Product information (PDF)

Product information (PDF)