Product Description

ÖLFLEX® TRUCK 170 TWIN

ÖLFLEX® HEAT 180 SiF

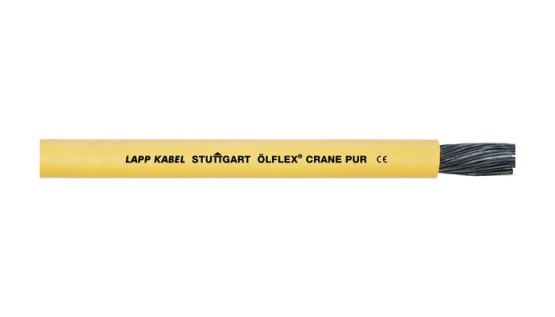

ÖLFLEX® CRANE PUR

Reelable polyurethane cables for low, medium and high mechanical stress

Designed with a smaller outer diameter to save space and weight; Cost-saving due to the use of smaller drums, guide rollers, as well as drive engines when possible; Reeling, unreeling and guiding operations also impose tensile stresses on the cables; The central supporting element absorbs the tensile loads that occur, thereby allowing reeling, unreeling and deflection for free-hanging cables even over large distances; Integrated supporting braid prevents undesirable cable twists, and the formation of so-called corkscrew effects

- Multifunctional application possibilities

- Lightweight due to minimiseddiameters

- Halogen-free

|

|

|

|

|

|

|

|

|

|

|

|

|

SKU: 100000127

Categories: CABLES & ACCESSORIES, Conveyor technology, Power and control cables, Reelable

Article List

Product description

Technical Data

| Lapp No. | Product Name | Datasheet / Product video | Request Quote | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Number of cores and mm² per conductor | Outer diameter (mm) | Tensile strength (N) | Copper index (kg/km) | Weight (kg/km) | |||||

| ÖLFLEX® CRANE PUR | |||||||||

| Lapp 0045207 | ÖLFLEX CRANE PUR 4 G 1,5 | ||||||||

| 4 G 1,5 | 10.9 | 500 | 57.6 | 169 | |||||

| Lapp 0045209 | ÖLFLEX CRANE PUR 5 G 1,5 | ||||||||

| 5 G 1,5 | 11.6 | 1000 | 72.0 | 197 | |||||

| Lapp 0045210 | ÖLFLEX CRANE PUR 7 G 1,5 | ||||||||

| 7 G 1,5 | 12.9 | 2500 | 100.8 | 239 | |||||

| Lapp 0045211 | ÖLFLEX CRANE PUR 12 G 1,5 | ||||||||

| 12 G 1,5 | 17.6 | 2500 | 172.8 | 401 | |||||

| Lapp 0045212 | ÖLFLEX CRANE PUR 18 G 1,5 | ||||||||

| 18 G 1,5 | 17.5 | 2500 | 259.2 | 507 | |||||

| Lapp 0045213 | ÖLFLEX CRANE PUR 24 G 1,5 | ||||||||

| 24 G 1,5 | 20.7 | 2500 | 345.6 | 673 | |||||

| Lapp 0045215 | ÖLFLEX CRANE PUR 30 G 1,5 | ||||||||

| 30 G 1,5 | 28.9 | 3000 | 432.0 | 1100 | |||||

| Lapp 0045214 | ÖLFLEX CRANE PUR 36 G 1,5 | ||||||||

| 36 G 1,5 | 31.4 | 3000 | 518.4 | 1350 | |||||

| Lapp 0045216 | ÖLFLEX CRANE PUR 4 G 2,5 | ||||||||

| 4 G 2,5 | 12.2 | 500 | 96.0 | 227 | |||||

| Lapp 0045218 | ÖLFLEX CRANE PUR 5 G 2,5 | ||||||||

| 5 G 2,5 | 13.2 | 2000 | 120.0 | 274 | |||||

| Lapp 0045220 | ÖLFLEX CRANE PUR 7 G 2,5 | ||||||||

| 7 G 2,5 | 15.4 | 3000 | 168.0 | 358 | |||||

| Lapp 0045221 | ÖLFLEX CRANE PUR 12 G 2,5 | ||||||||

| 12 G 2,5 | 21.6 | 3000 | 288.0 | 619 | |||||

| Lapp 0045222 | ÖLFLEX CRANE PUR 18 G 2,5 | ||||||||

| 18 G 2,5 | 21.5 | 3000 | 432.0 | 793 | |||||

| Lapp 0045223 | ÖLFLEX CRANE PUR 24 G 2,5 | ||||||||

| 24 G 2,5 | 25.5 | 3000 | 576.0 | 1123 | |||||

| Lapp 0045224 | ÖLFLEX CRANE PUR 30 G 2,5 | ||||||||

| 30 G 2,5 | 34.7 | 3000 | 720.0 | 1641 | |||||

| Lapp 0045225 | ÖLFLEX CRANE PUR 4 G 4 | ||||||||

| 4 G 4 | 14.3 | 1000 | 153.6 | 341 | |||||

| Lapp 0045227 | ÖLFLEX CRANE PUR 5 G 4 | ||||||||

| 5 G 4 | 15.5 | 2000 | 192.0 | 411 | |||||

| Lapp 0045228 | ÖLFLEX CRANE PUR 4 G 6 | ||||||||

| 4 G 6 | 16.6 | 1500 | 230.4 | 457 | |||||

| Lapp 0045229 | ÖLFLEX CRANE PUR 5 G 6 | ||||||||

| 5 G 6 | 17.7 | 2000 | 288.0 | 538 | |||||

| Lapp 0045235 | ÖLFLEX CRANE PUR 7 G 6 | ||||||||

| 7 G 6 | 21.5 | 403.0 | 750 | ||||||

| Lapp 0045230 | ÖLFLEX CRANE PUR 4 G 10 | ||||||||

| 4 G 10 | 19.2 | 2000 | 384.0 | 674 | |||||

| Lapp 0045237 | ÖLFLEX CRANE PUR 5 G 10 | ||||||||

| 5 G 10 | 21.6 | 2500 | 480.0 | 825 | |||||

| Lapp 0045231 | ÖLFLEX CRANE PUR 4 G 16 | ||||||||

| 4 G 16 | 22.2 | 2500 | 614.4 | 966 | |||||

| Lapp 0045238 | ÖLFLEX CRANE PUR 5 G 16 | ||||||||

| 5 G 16 | 25.6 | 3500 | 768.0 | 1222 | |||||

| Lapp 0045232 | ÖLFLEX CRANE PUR 4 G 25 | ||||||||

| 4 G 25 | 27.6 | 3500 | 960.0 | 1506 | |||||

| Lapp 0045233 | ÖLFLEX CRANE PUR 4 G 35 | ||||||||

| 4 G 35 | 31.0 | 4500 | 1344.0 | 2004 | |||||

| Lapp 0045234 | ÖLFLEX CRANE PUR 4 G 50 | ||||||||

| 4 G 50 | 36.1 | 6000 | 1920.0 | 2838 | |||||

| Lapp 0045240 | ÖLFLEX CRANE PUR 3×25+3G6 | ||||||||

| 3×25+3G6 | 25.7 | 2000 | 892.8 | 1380 | |||||

| Lapp 0045241 | ÖLFLEX CRANE PUR 3×35+3G6 | ||||||||

| 3×35+3G6 | 27.6 | 2500 | 1180.8 | 1695 | |||||

| Lapp 0045242 | ÖLFLEX CRANE PUR 3×50+3G10 | ||||||||

| 3×50+3G10 | 32.1 | 3500 | 1728.0 | 2307 | |||||

Application range

- For use in hoists, transport and conveyor

systems - Cables are reeled, unreeled, and guided by roller trains

- In dry or damp interiors, outdoors, or not more than 2 weeks without interruption in industrial water

- The application profiles for ÖLFLEX® CRANE and ÖLFLEX(R) LIFT cables can be found in the appendix, selection table A3

- The assembly and handling guidelines for ÖLFLEX® CRANE cables can be found in the catalogue appendix, technical table T4; for ÖLFLEX(R) LIFT cables please see the catalogue appendix, technical table T5

Benefits

- Designed with a smaller outer diameter to save space and weight

- Cost-saving due to the use of smaller drums, guide rollers, as well as drive engines when possible

- Reeling, unreeling and guiding operations also impose tensile stresses on the cables

- The central supporting element absorbs the tensile loads that occur, thereby allowing reeling, unreeling and deflection for free-hanging cables even over large distances.

- Integrated supporting braid prevents undesirable cable twists, and the formation of so-called corkscrew effects

Product Make-up

- Strands of bare copper wires

- Core insulatoin: TPE compound

- Central supporting element

- Support braid integrated in the outer sheath

- Outer sheath: PUR compound, halogen-free

Product features

- Halogen-free and flame-retardant

(IEC 60332-1-2) - Oil-resistant according to EN 60811-404

- Good chemical, thermal and mechanical-resistance

- For connecting mobile equipment in hazardous areas acc. to DIN VDE 0165

| Core identification code | Up to 5 cores: colour-coded according to VDE 0293-308, refer to Appendix T9 From 6 cores: black with white numbers |

| Classification | ETIM 5.0 Class-ID: EC000057 ETIM 5.0 Class-Description: Low voltage power cable |

| Conductor stranding | Extra-fine wire according to VDE 0295, class 6/IEC 60228 class 6 |

| Minimum bending radius | Flexible use: 7.5 x outer diameter |

| Nominal voltage | U0/U: 600/1000 V |

| Test voltage | 3500 V |

| Protective conductor | G = with GN-YE protective conductor X = without protective conductor |

| Current rating | VDE 298 Part 4 |

| Temperature range | Flexible use: -40°C Max. cond. temperature: +80°C |

Product information (PDF)

Product information (PDF)