Product Description

ÖLFLEX® LIFT

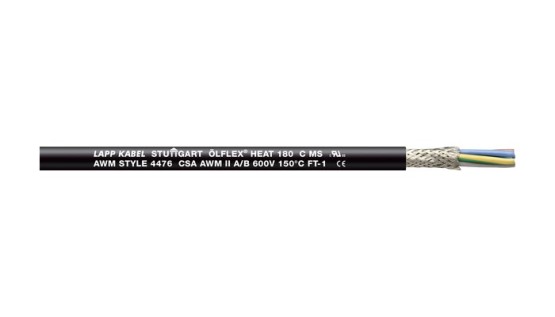

ÖLFLEX® HEAT 180 C MS

Screened and approved silicone cables for North America (AWM recognized)

Certified for the USA and Canada for export-oriented appliance and apparatus manufacturers; Thicker cable design meets the requirements of the FT-1 flame test and also approved for the external interconnection of apparatuses and appliances; Flexibility simplifies installation where space is limited; Copper braiding screens the cable against

electromagnetic interference

- MS = Multi-Standard For use in the USA and Canada

- UL AWM Style 4476 (150 °C/600V)

- EMC compliant copper screening

|

|

|

|

|

|

|

|

SKU: 100000142

Categories: CABLES & ACCESSORIES, Expanded ambient temperatures, Power and control cables, Silicone cables (-50°C to +180°C)

Article List

Product description

Technical Data

| Lapp No. | Product Name | Datasheet / Product video | Request Quote | ||||

|---|---|---|---|---|---|---|---|

| Number of cores and mm² per conductor | Outer diameter (mm) | Copper index (kg/km) | Weight (kg/km) | ||||

| ÖLFLEX® HEAT 180 C MS | |||||||

| Lapp 0046701 | ÖLFLEX HEAT 180 C MS 3 G 0,5 | ||||||

| 3 G 0,5 | 8,6 | 43.4 | 100 | ||||

| Lapp 0046702 | ÖLFLEX HEAT 180 C MS 4 G 0,5 | ||||||

| 4 G 0,5 | 9,3 | 55.4 | 122 | ||||

| Lapp 0046703 | ÖLFLEX HEAT 180 C MS 5 G 0,5 | ||||||

| 5 G 0,5 | 10.0 | 60.2 | 137 | ||||

| Lapp 0046708 | ÖLFLEX HEAT 180 C MS 2 X 1 | ||||||

| 2 X 1 | 9.0 | 48.2 | 104 | ||||

| Lapp 0046709 | ÖLFLEX HEAT 180 C MS 3 G 1 | ||||||

| 3 G 1 | 9,5 | 65.0 | 131 | ||||

| Lapp 0046710 | ÖLFLEX HEAT 180 C MS 4 G 1 | ||||||

| 4 G 1 | 10,2 | 74.6 | 152 | ||||

| Lapp 0046711 | ÖLFLEX HEAT 180 C MS 5 G 1 | ||||||

| 5 G 1 | 11.0 | 91.5 | 181 | ||||

| Lapp 0046712 | ÖLFLEX HEAT 180 C MS 7 G 1 | ||||||

| 7 G 1 | 11,9 | 117.9 | 228 | ||||

| Lapp 0046716 | ÖLFLEX HEAT 180 C MS 2 X 1,5 | ||||||

| 2 X 1,5 | 9,6 | 65.0 | 126 | ||||

| Lapp 0046717 | ÖLFLEX HEAT 180 C MS 3 G 1,5 | ||||||

| 3 G 1,5 | 10,1 | 79.4 | 152 | ||||

| Lapp 0046718 | ÖLFLEX HEAT 180 C MS 4 G 1,5 | ||||||

| 4 G 1,5 | 10,9 | 101.1 | 186 | ||||

| Lapp 0046719 | ÖLFLEX HEAT 180 C MS 5 G 1,5 | ||||||

| 5 G 1,5 | 11,8 | 122.7 | 222 | ||||

| Lapp 0046720 | ÖLFLEX HEAT 180 C MS 7 G 1,5 | ||||||

| 7 G 1,5 | 12,8 | 158.7 | 281 | ||||

| Lapp 0046721 | ÖLFLEX HEAT 180 C MS 12 G 1,5 | ||||||

| 12 G 1,5 | 16,9 | 245.2 | 431 | ||||

| Lapp 0046723 | ÖLFLEX HEAT 180 C MS 18 G 1,5 | ||||||

| 18 G 1,5 | 19,6 | 346.1 | 600 | ||||

| Lapp 0046724 | ÖLFLEX HEAT 180 C MS 25 G 1,5 | ||||||

| 25 G 1,5 | 23,9 | 495.7 | 833 | ||||

| Lapp 0046728 | ÖLFLEX HEAT 180 C MS 3 G 2,5 | ||||||

| 3 G 2,5 | 11.0 | 115.5 | 197 | ||||

| Lapp 0046729 | ÖLFLEX HEAT 180 C MS 4 G 2,5 | ||||||

| 4 G 2,5 | 11,9 | 146.7 | 244 | ||||

| Lapp 0046730 | ÖLFLEX HEAT 180 C MS 5 G 2,5 | ||||||

| 5 G 2,5 | 12,9 | 177.9 | 291 | ||||

| Lapp 0046734 | ÖLFLEX HEAT 180 C MS 3 G 4 | ||||||

| 3 G 4 | 12,3 | 165.9 | 261 | ||||

| Lapp 0046735 | ÖLFLEX HEAT 180 C MS 4 G 4 | ||||||

| 4 G 4 | 13,4 | 211.5 | 325 | ||||

| Lapp 0046736 | ÖLFLEX HEAT 180 C MS 5 G 4 | ||||||

| 5 G 4 | 14,9 | 257.2 | 389 | ||||

| Lapp 0046740 | ÖLFLEX HEAT 180 C MS 4 G 6 | ||||||

| 4 G 6 | 17,2 | 302.8 | 482 | ||||

| Lapp 0046741 | ÖLFLEX HEAT 180 C MS 5 G 6 | ||||||

| 5 G 6 | 18,7 | 367.6 | 580 | ||||

| Lapp 0046742 | ÖLFLEX HEAT 180 C MS 4 G 10 | ||||||

| 4 G 10 | 22,8 | 508.4 | 802 | ||||

Application range

- Areas with high ambient temperatures where insulating and sheath materials of conventional cables will embrittle after a short while

- Typical fields of application

– Steel, ceramic and iron works

– Bakery equipment and industrial furnaces

– Electric motor industry

– Sauna/solarium construction

– Thermal and heating elements

– Lighting technology

– Ventilator engineering

– Air-conditioning technology

– Galvanisation technology

Benefits

- Certified for the USA and Canada for export-oriented appliance and apparatus manufacturers

- Thicker cable design meets the requirements of the FT-1 flame test and also approved for the external interconnection of apparatuses and appliances

- Flexibility simplifies installation where space is limited

- Copper braiding screens the cable against

electromagnetic interference

Product Make-up

- Fine-wire, tinned-copper conductor

- Silicone-based core insulation

- Cores twisted together

- Tinned-copper screen braiding,

interleaved plastic foil wrapping - Silicone-based outer sheath,

colour black

Norm references / Approvals

- UL AWM 4476 and cUL AWM II A/B

Construction B, External interconnection

Product features

- Metric flexible conductor design

- Halogen-free and flame-retardant

(IEC 60332-1-2) - Good hydrolysis and UV-resistance

- Resistant to a multitude of oils, alcohols, vegetable and animal fats and chemical substances

| Core identification code | Colours according to VDE 0293-308, refer to Appendix T9 From 6 cores: black with white numbers |

| Classification | ETIM 5.0 Class-ID: EC001578 ETIM 5.0 Class-Description: Flexible cable |

| Conductor stranding | Fine wire according to VDE 0295, class 5/IEC 60228 class 5 (Refer to Appendix T16 for the matching US conductor sizes in AWG standard) |

| Minimum bending radius | Occasional flexing: 20 x outer diameter Fixed installation: 6 x outer diameter |

| Nominal voltage | U0/U: 300/500 V Working voltage UL: 600 V |

| Test voltage | 2000 V |

| Protective conductor | G = with GN-YE protective conductor X = without protective conductor |

| Temperature range | According to VDE: -50 °C to +180 °C Normatively acc. UL Style: up to +150°C (adequate ventilation required) |

Product information (PDF)

Product information (PDF)